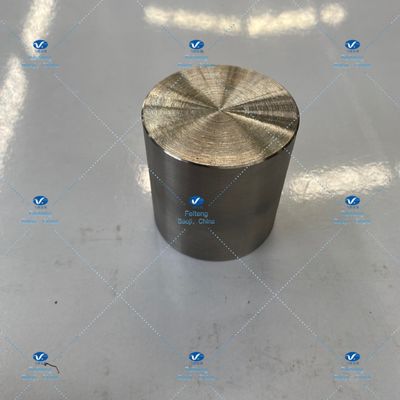

55OD*57L High Mechanical Strength Titanium Bars ODM

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Bars |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Name | Titanium Bars | Advantage | Light Quality,High Strengthen Anticorrossive,Corrosion Resistance,acid And Base Resistance |

|---|---|---|---|

| Shape | Round | Size | φ55*57 |

| Grade | Gr5 | Package | Wooden Case |

| Application | Industrial,Medical,exhaust Hanger,chemical,Condenser | Specification | ASTM B348 |

| High Light | High Mechanical Strength Titanium Bars,55OD*57L Titanium Bars,dia 55mm Titanium Bar ODM |

||

Titanium Bars Gr5 ASTM B348-06 a 55OD*57L Titanium Forging Titanium Round Rod Titanium Products

|

Name |

Titanium Bars |

|

Grade |

Gr5 |

|

Transport Package |

Wooden case |

|

Origin |

Baoji, Shaanxi, China |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Shape | Round |

Titanium has metallic luster and ductility. Titanium is characterized by low density, high mechanical strength and easy machining. The plasticity of titanium depends to a large extent on its purity. The more pure titanium, the stronger its plasticity. Good corrosion resistance, free from atmosphere and seawater. At room temperature, it is not corroded by hydrochloric acid below 7%, sulphuric acid below 5%, nitric acid, aqua regia or dilute alkali solution. Only hydrofluoric acid, concentrated hydrochloric acid and concentrated sulfuric acid can act on it. The presence of impurities in titanium greatly affects its mechanical properties, especially interstitial impurities (oxygen, nitrogen and carbon) can greatly enhance the strength of titanium and significantly reduce its plasticity. As a structural material, titanium can obtain good mechanical properties by strictly controlling the impurity content and adding alloying elements.

Titanium rod has good thermal strength, good weldability and excellent corrosion resistance. Its disadvantage is low strength at room temperature. It is usually used as a heat-resistant and corrosion-resistant material. Titanium alloys are widely used in various fields due to their high specific strength, good corrosion resistance and good heat resistance. The industrial production of titanium began in 1948. The demand of aviation industry makes the titanium industry develop at an average annual rate of about 8%. At present, the annual output of international titanium alloy processing materials has reached 4 million tons, and there are nearly 30 kinds of titanium alloy trademarks. Titanium alloys are mainly used for aircraft engine compressor parts, followed by rocket, missile and high-speed aircraft layout parts. In the mid 1960s, titanium and its alloys were used in general industries such as electrolytic industrial electrodes, power station condensers, refining and desalting heaters, and environmental pollution control equipment. Titanium and its alloys have become an anticorrosive material.

Product advantages

1. Convenient handling.

2. Strong corrosion resistance

3. low fluid resistance

4. High mechanical strength